Trying to figure out what was causing my rudder cable to rub was a lot of work. About 3 days wasted. (I can count these hours towards the plane build right? Even if I am redoing things, or just staring at the plane itching my head? ) I’ll admit I couldn’t figure it out. So I took to the Sling Builders Facebook group to get ideas. A lot of people really stepped up to help out and give great ideas, thanks to Oliver and Midwest Sky sports. But it was an unexpected phone call from Jean that sent me down the right path. He suggested checking the sliding plates under the luggage floor where the springs connect. The suggestion was to disconnect the springs and then loosen the sliders. And then position the sliders where the stops on the cable naturally fall. So what this accomplished was that the cable going to the rudder on the opposite side that is being pulled, has very little pressure on it. So it may in fact be rubbing or touching but it has very little pressure therefore it won’t cut through/wear. He did also mention that if my rudder is correctly configured it should more or less auto center. At that point in time I couldn’t even imagine that ever happening because I was nowhere near that. I used the luggage weighing device and I measured how much force it was taking to turn my front wheel even while in the air…. Using the hole for the tow attachment,, it was taking 35 lb of force to turn my front wheel…. That is ridiculous…

So for the fifth time I dropped my front wheel and sanded down the bearings… That helped a lot… But still not enough… So I also remove the pedals and sanded down those bearings… I used to micrometer to make sure I didn’t take too much off. I sanded them down from 5.6 to 5.45mm. Then I haf to reattach the pedals and reattach the front wheel l. Now as if by some sort of magic my rudder auto centers, barely. Which to this novice is perfect. Now the front wheel while in the air takes 5lbs of pressure to turn.

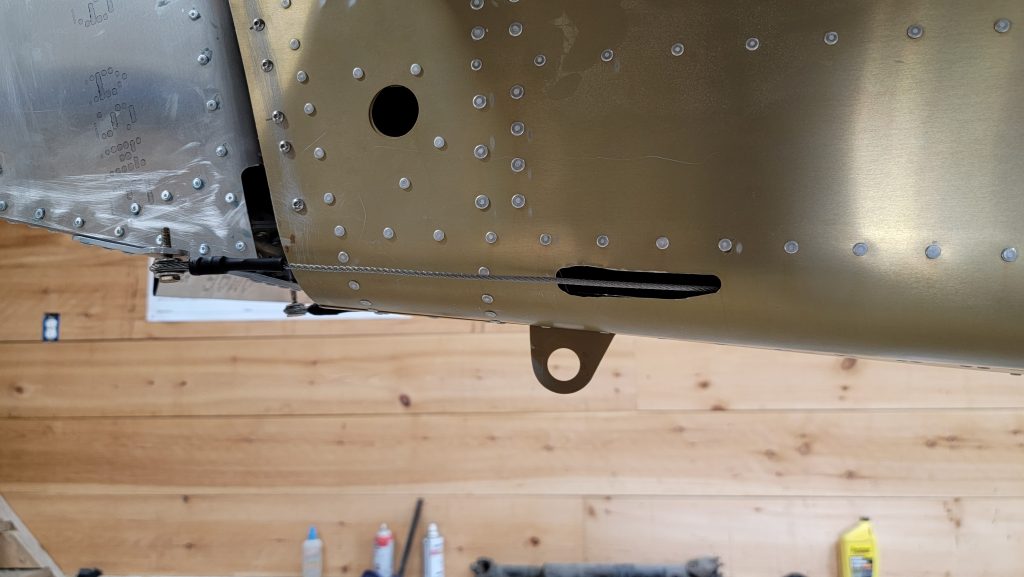

The cable going to the rudder, where it comes out of the rear fuselage, in my opinion was still rubbing too much. So I made the whole a little wider and a little further back. Jean also said this would be fine. I’m going to make a special piece of plastic to go over this hole which will make it look exactly like a normal hole. It’ll be just like the plastic (polypropylene sheet 3mm thick Amazon) that comes from the factory except a little bit wider. Should be a fun project for my Rotozip. To make the hole in the fuselage a little bit bigger, I was extremely nervous. But luckily this tool called a biter just made it like cutting butter, I could do it accurately and easily it was incredible.

Jean thank you for calling me after hours, your time, and spending 30 minutes listening to me uneducatedly babble about my problem. Your suggestions were invaluable. Thank you, Thank you.

okay, for documentation sake, and helping to spread understanding, here is a picture of the rudder slide control ,,

rudder centered below,

rudder full right below,

rudder full left,

Leave a Reply