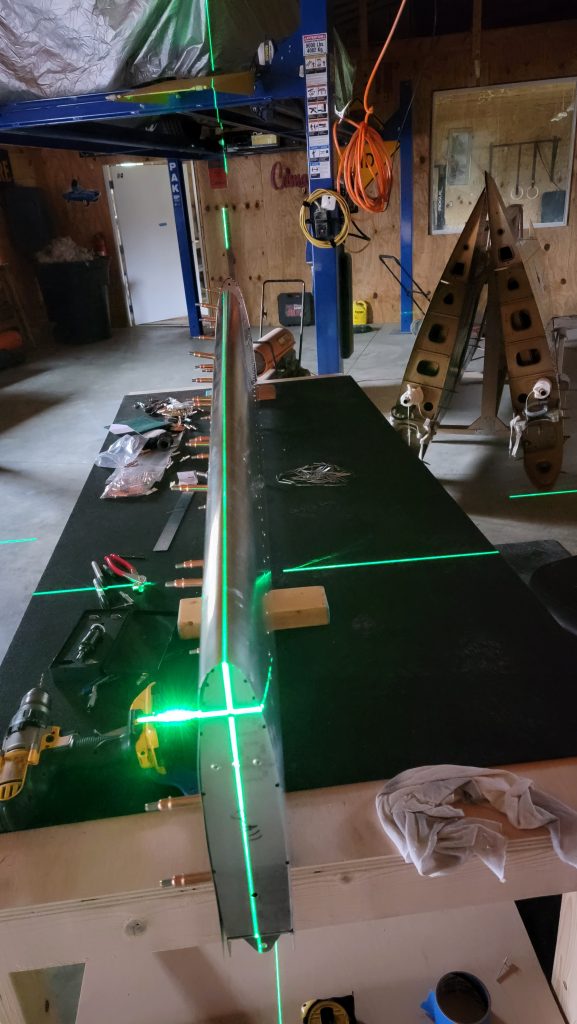

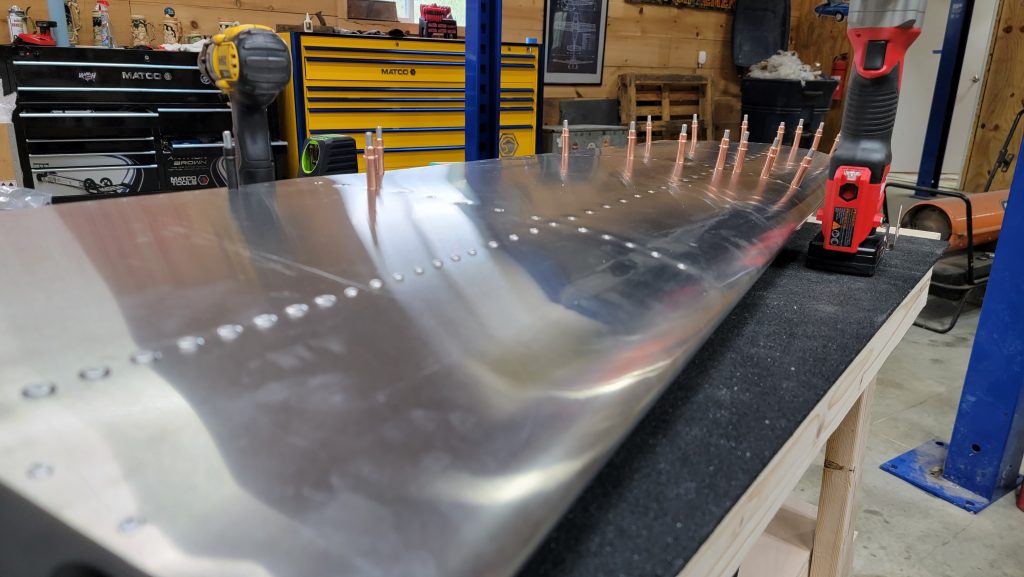

20hrs. It was fun and rewarding to get the first part of my plane out of the way but also very tiring. I did go ahead and prime the meeting surfaces. I cleaned them with green cleaner and acetone them and self etching primer them. I didn’t plan on doing that but I decided since the airplane factory allodined the rest that was the least I could do. I did have to put in an email to Jean in California. He called me back just 15 minutes later,,,great customer service,,,and he was able to answer a question I had about drilling out some of the pre-dimpled holes. The called for rivet wouldn’t fit in the pre-dimpled hole but apparently it has to be reamed out. After all that was straightened out, and a bunch more cleco’s put in, I checked with a laser level,, everything looked great!! Close it up with rivets on both sides and it looked great. Calling it a night.

Leave a Reply