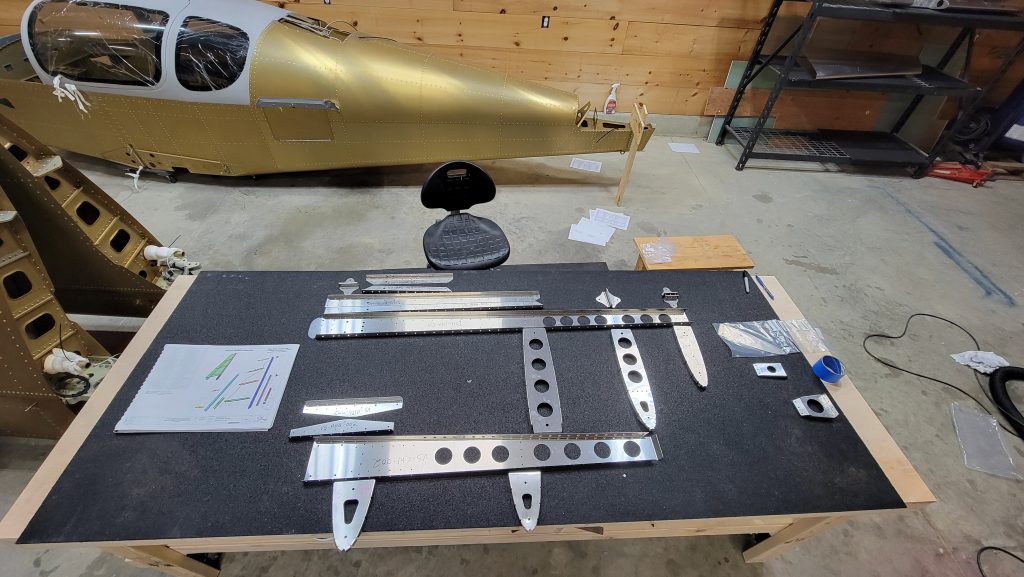

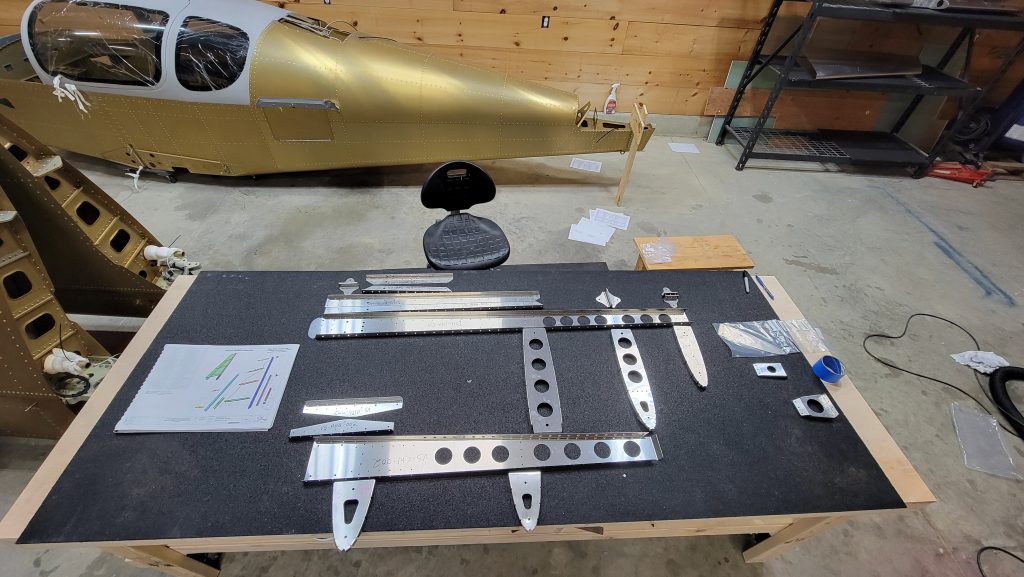

All laid out and ready for tomorrow.

For now,,, time to put the kids to bed.

Custom Build

All laid out and ready for tomorrow.

For now,,, time to put the kids to bed.

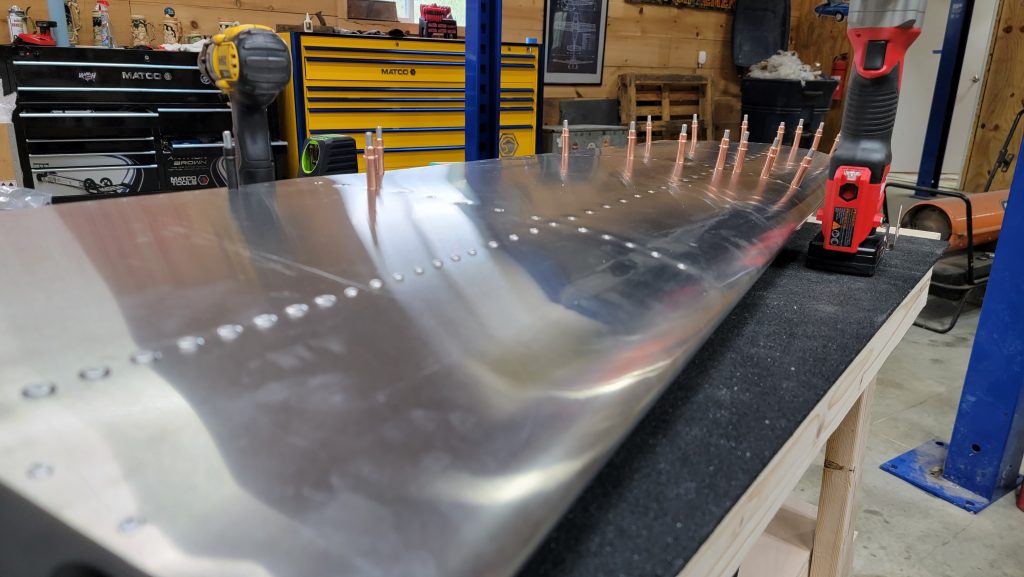

It was the best of times, it was the worst of times… I got as far as I could on the elevator. My elevator trim tab is missing, on backorder. And one of my elevators side skins is missing. But I was able to make most of the elevator. I did prime the inside mating surfaces. But I am just priming the surfaces that attach to the skin. Even if the priming isn’t necessary because the aluminum is 6061…. I think priming would help to smooth over any tiny burrs… I can’t feel any burrs with my hands. I’m impressed with the quality of the product that sling sends out it is all cut very smoothly. If I do find any burrs or make any myself of course I debur it. But I feel a layer of paint can’t hurt. Sadly I did put eight rivets in too soon. So I had to drill them out. It wasn’t a mistake in the instructions. It was just me reading incorrectly. So I have tried to slow down and do better going forward. I also did the safety wire through the end of the piano hinge for the elevator trim like others have suggested.

Yesterday, I was not able to work on the plane because I had to fly a plane. I did an hour flight South and then I was supposed to come back. I was flying my friends Cirrus SR20. It recently had a new engine put in it. And on the way there the oil pressure raised into the danger zone… The higher the oil pressure went, the higher my heart rate went. The oil pressure steadily increased about 1 psi every 5 minutes so I set myself a mental limit. And said if it exceeded the limit. I was going to land. It exceeded it so I put it down at the nearest airport which of course was not a convenient location. Then we got a rental car and drove 3 hours back home. To make matters more stressful, I had my 7-year-old, in one of the pictures below, flying with me.

But I’m back home now safely I will figure out what was wrong with the plane and I continue to work on the Sling.

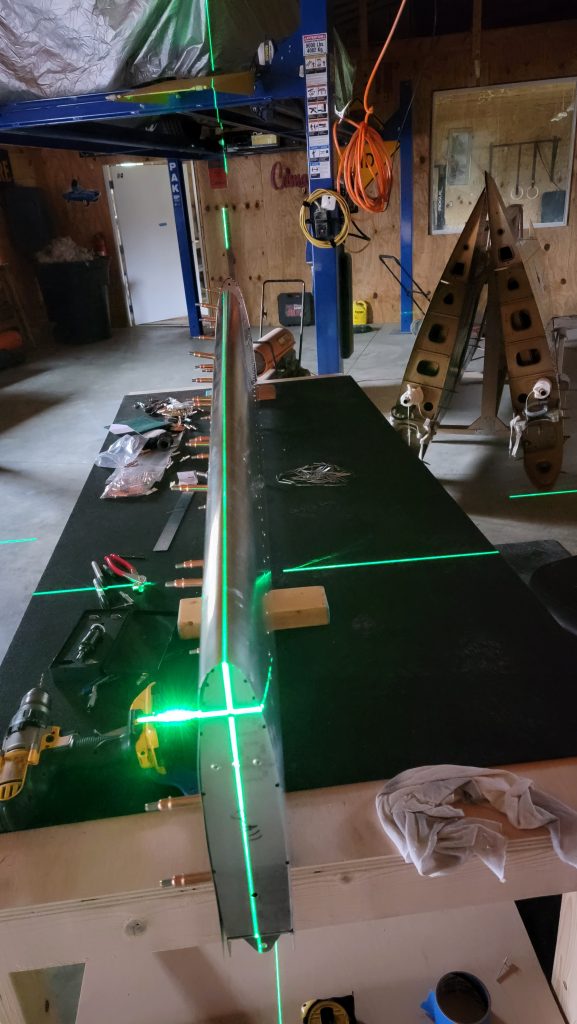

20hrs. It was fun and rewarding to get the first part of my plane out of the way but also very tiring. I did go ahead and prime the meeting surfaces. I cleaned them with green cleaner and acetone them and self etching primer them. I didn’t plan on doing that but I decided since the airplane factory allodined the rest that was the least I could do. I did have to put in an email to Jean in California. He called me back just 15 minutes later,,,great customer service,,,and he was able to answer a question I had about drilling out some of the pre-dimpled holes. The called for rivet wouldn’t fit in the pre-dimpled hole but apparently it has to be reamed out. After all that was straightened out, and a bunch more cleco’s put in, I checked with a laser level,, everything looked great!! Close it up with rivets on both sides and it looked great. Calling it a night.

I watched my ship arrive at the port of Norfolk. It was scheduled for 4/19 but arrived on 4/12. A welcome surprise. Two days later I received a phone call asking when they could deliver my container. I said as soon as you can. They scheduled it for 4 days later at 10am. I was skeptical that they would not be late… but they made it here .

Myself, three very kind friends, and a forklift helped unload. Thanks be to Scott Johnson at TOA for telling me I would need #2 and #3 square bits to back out the 15 lbs of screws that they used to attach it. The surprise gift was the tremendous amount of beautiful lumber that was used to secure the shipment. I believe its mahagony. But whatever it is, it’s beautiful wood. By the time we backed out all the screws and unloaded we were all very tired. Unloading took just under 2 hours. Which I am told is the max time allowed without incurring additional charges.

It’s building time !!

My ship was supposed to dock 4/6. But then it got pushed to 4/19. But managed to dock on 4/12 Today 4/13 I got a call from the freight forwarder saying to expect delivery to my house on 4/18. So needless to say I am ecstatic. So happy. Can’t wait.

Now I just need to find out where my under carriage kit is, cuz it accidentally didn’t ship in the container. My firewall forward kit should be here later this month. And avionics should be in Aug.

Things are looking up.

The boat that was supposed to pick it up, didn’t. again. this is the fourth time this has happened. .. end transmission…

My container is still on the dock in Hamburg. According to the shipping itinerary it was supposed to be picked up yesterday by the Al Safat. But for whatever reason it was not. So now it just sits on the dock for another two weeks. Until another ship is ‘supposed’ to pick it up. ( This is the fourth time is type of delay has happened, albeit at other ports. ) and sadly the journey is only half done. So it is impossible to tell how many more delays there will be. There is no way to determine when it might even approximately be delivered. I have found this lack of predictability very challenging when trying to schedule and plan aircraft building and normal life things in the future.

So I guess my advice would be to any future kit purchasers…

… … …

Because if you can’t do some version of the above. and you check the tracking status of your container every 5 minutes for half a year, like I do. You will slowly and certainly make yourself go insane.

My Sling TSI, after sitting at the port of Hamburg for two weeks, has left the port and is starting its journey across the Atlantic. My kit is in a container on the ship Al Safat. I was able to get a picture of it leaving the port. It should be at my port in Virginia in mid March.

The coolest thing !!

I do have a hangar. It is currently housing the Smoke House Pilots ( https://www.facebook.com/groups/1493756143990780 ) plane , that is my old plane (sold my plane to afford this venture ) that is currently in my hangar. I will be building most of the Sling TSI in my shop, at my home. For the final stages, I will be finishing the plane at the hangar.

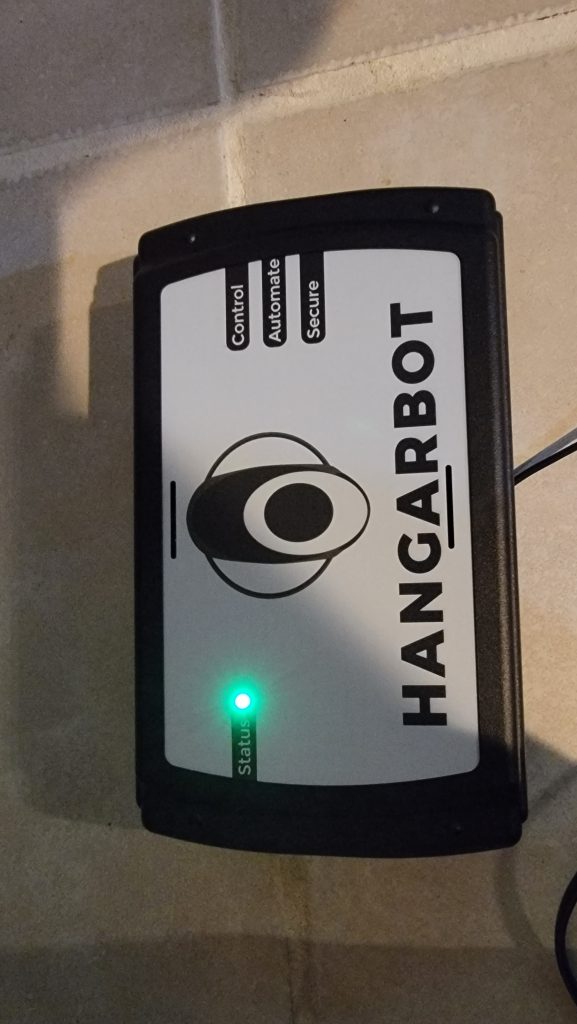

Sooo, to that end, I have acquired a way to keep the plane preheated during the winter. https://shop.hangarbot.com/ With the Cirrus that I currently have/use, we always preheat the plane during the winter when its below 40f. And to preheat properly, it takes a little bit. Getting to the hangar 2 hours before you wanna fly is a pain. So I got Hangarbot. It allows me to start the engine preheater before we arrive at the hangar !!! sweetttt !!! I was amazed at how easy this was to setup. It comes with a built in cellular connection that you don’t have to mess with. Just download the app, and log in… and boom it works. Amazing. Can’t recommend this product enough. Surprisingly easy ! Its suppose to be just for engine preheating… But I can’t help but to think about other things I can connect the outlet to.

Here are some pictures of my workshop. I made my modified EAA table. Its 3′ wide and 8′ long. I also put lockable casters on the bottom so I can move it.

DRDT-2 ! As you can tell from the pictures, for my dimpler I did not create a separate stand. I created two little blocks at the same height as the drdt-2. This should allow me to slide things through the dimpler while keeping them level and supported.

Also pictured is the wing holder on casters.

For the fun part… The ship that will be bringing my Sling TSI from Hamburg is pictured below. It is a picture of the ship in Rotterdam from a webcam, 3 days before its suppose to pick up my container in Hamburg. The previous ship dropped it off in Hamburg and this ship is suppose to pick it up ( if the Ukraine war doesn’t delay it ) take it across the Atlantic, to New York, then to Norfolk.

current approx eta 3 week in march

© 2026 Sling TSI from Quick Build

Theme by Anders Noren — Up ↑