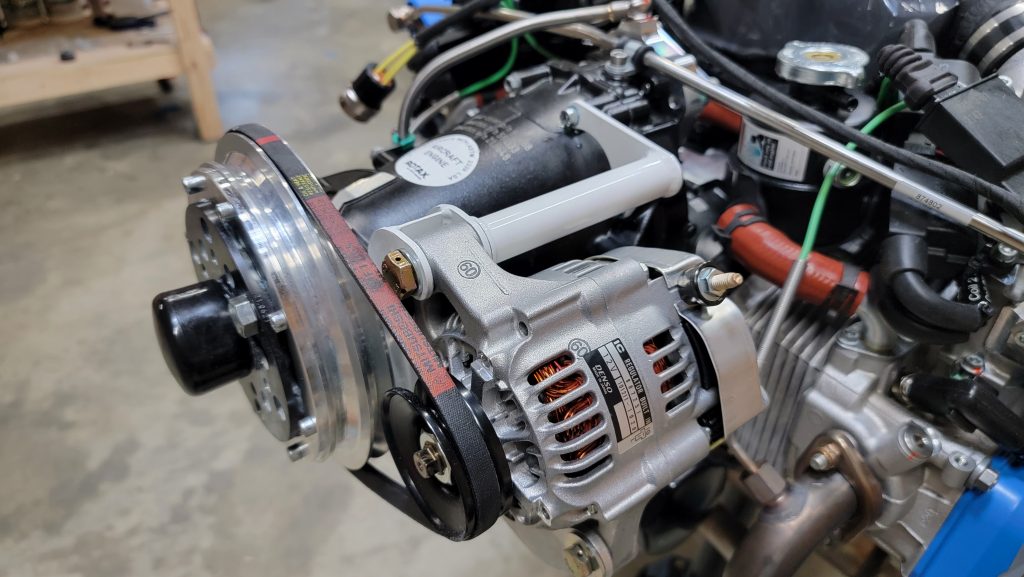

I chose to go with the external alternator for my Sling TSI. Both for the CG advantage and for having a tertiary backup alternator…. And for being able to run pitot heat and landing lights without worrying about running the battery dead.

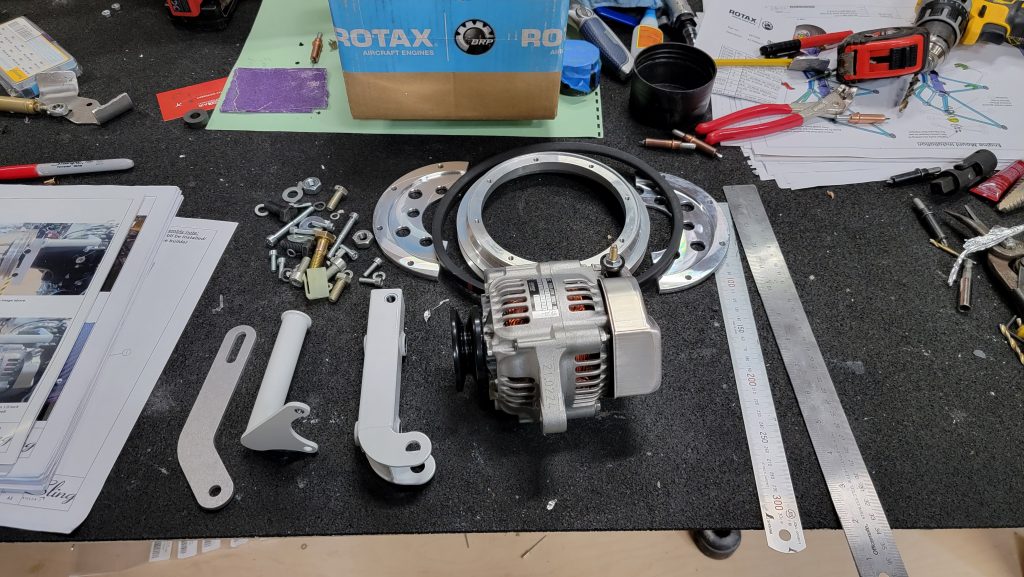

I couldn’t find many pictures of the installation online so here are pictures of mine. The installation of the external alternator is very straightforward. You will want to connect it with a separate switch so you don’t necessarily have to always run it.

Update: my alternator is bumping the cowling. I do have the cowling with the bump out but it still bumps. It was rubbing the cowling. Can’t have that. To fix the problem I got a 25.5 inch vbelt. Shorter than the default one. It allows the alternator to sit in closer. That said it is still crazy close.

I also did research into how much horsepower the external alternator would be stealing because our little engines only make 135 to 141 horsepower every single horsepower counts. After doing the math of (UPDATED🙂 my 1hp equals 768watt per 20amps, and not all alternators are created equal, we use denso… So basically we are losing 4hp with the ext alt. …. I came to the realization that we’re losing four horsepower. Of course I took into account that the alternator is not perfectly efficient and there will be some drag loss from the belt but even then you’re talking one to one and a half horsepower which I think is worth having the extra backup. Update, four horsepower, maybe it isn’t worth it….