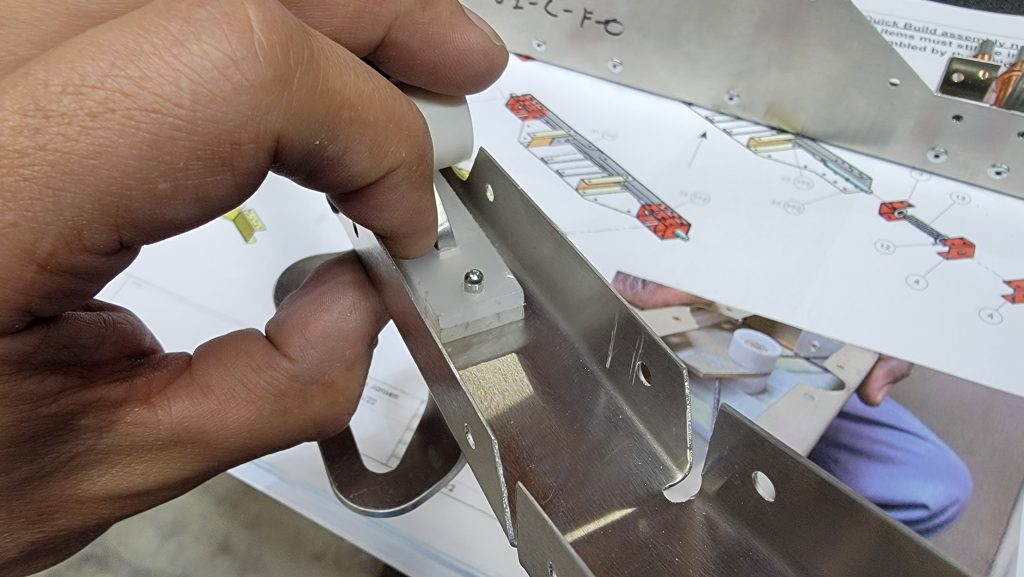

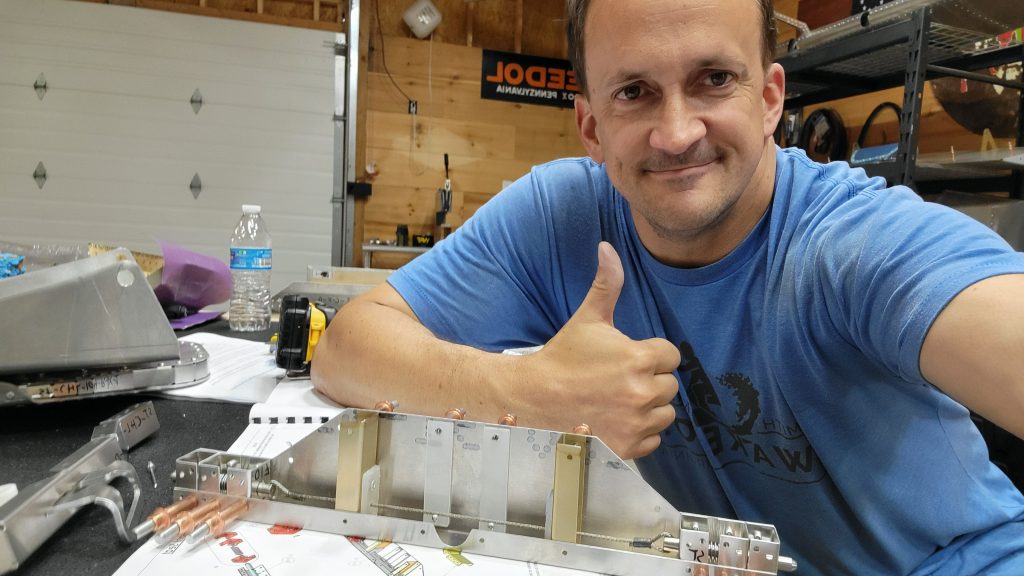

I have very few things I can actually do at this point… The one remaining thing was/is installing the taxi/landing lights. I found screwing them in with the spring behind the lights, in that tight hole, very challenging. So I rtv’d/glued the springs fast to the light bracket and left them all dry. Then put the back bracket in, then the light, then the front bracket, then the screw.

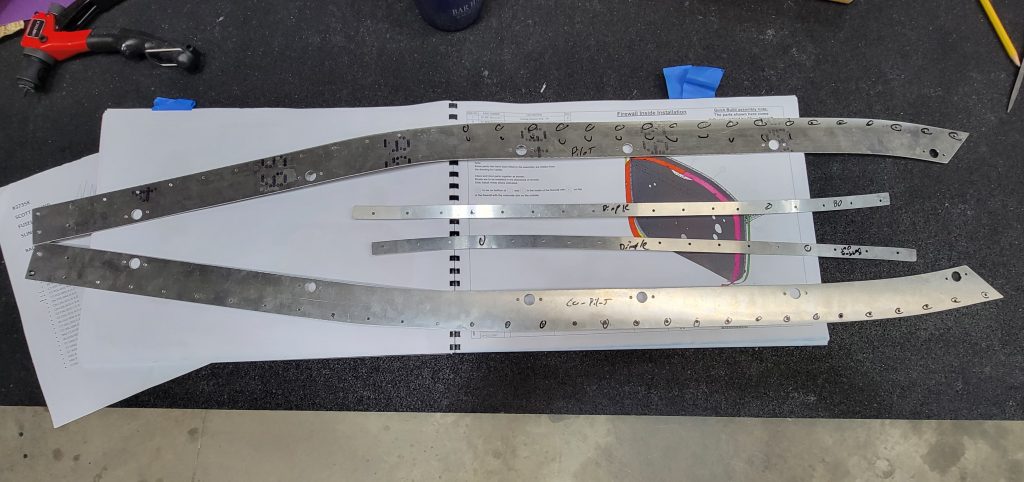

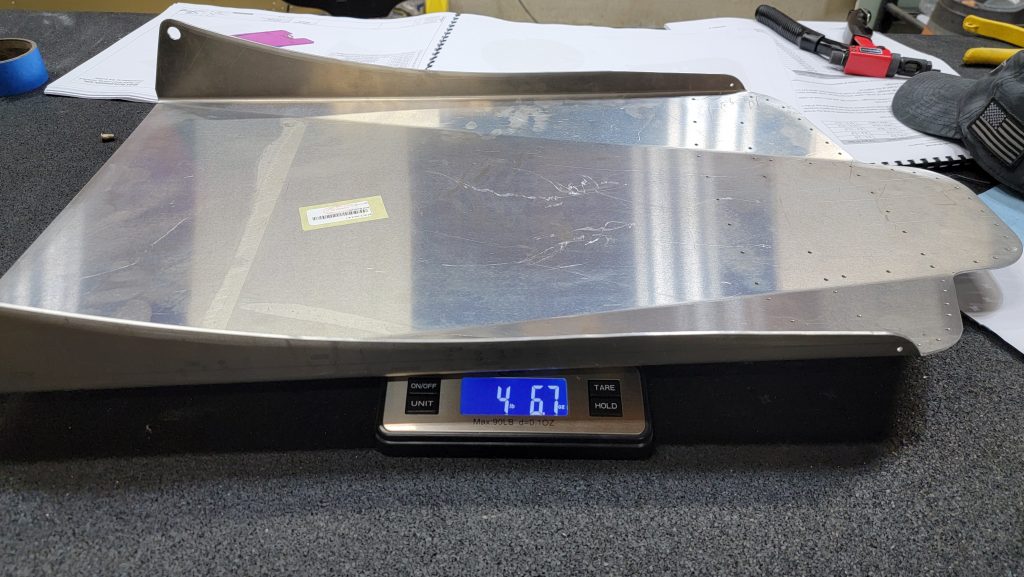

I’m missing so many parts. There are just no more fronts that I can make any more progress on. I do not have my undercarriage kit, I’m missing parts for the rear seat I’m missing parts for the front seat channels, a missing parts for the latches on the canopy door, I’m missing the flap control tube that goes in the cabin, I am missing pieces for the center console skins, still waiting on my interior, still waiting in the firewall forward but hopefully that’ll be here soon…. I think I’m at a dead end. Ugh.